|

|

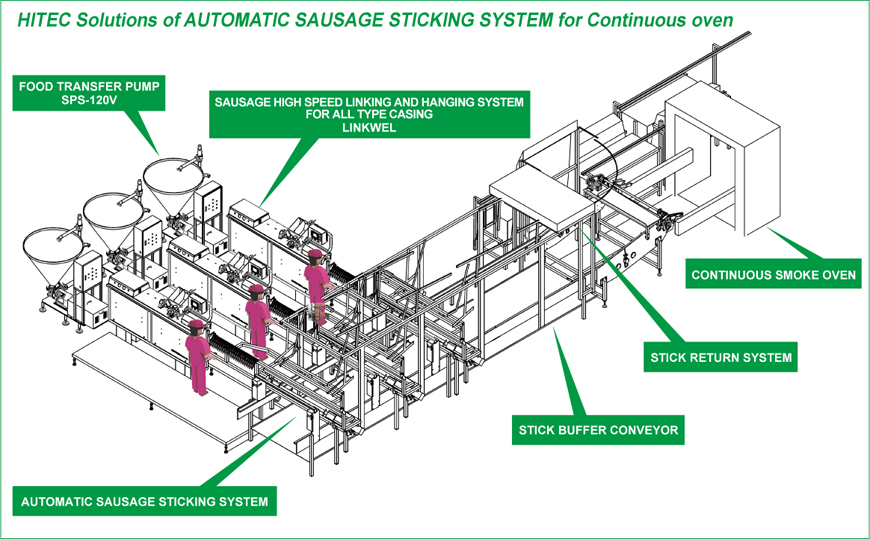

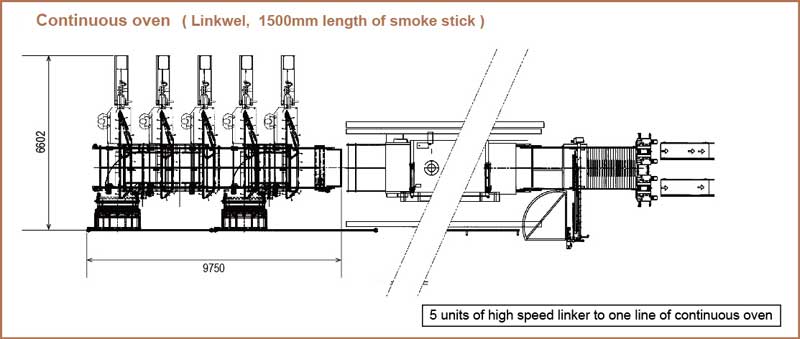

| Cycle time per stick・・・Approx. 4~5 sec/stick (per 1 production line of continuous smoke house) Casing Type・・・Natural casing, Collagen casing, Cellulose casing |

|

|

|

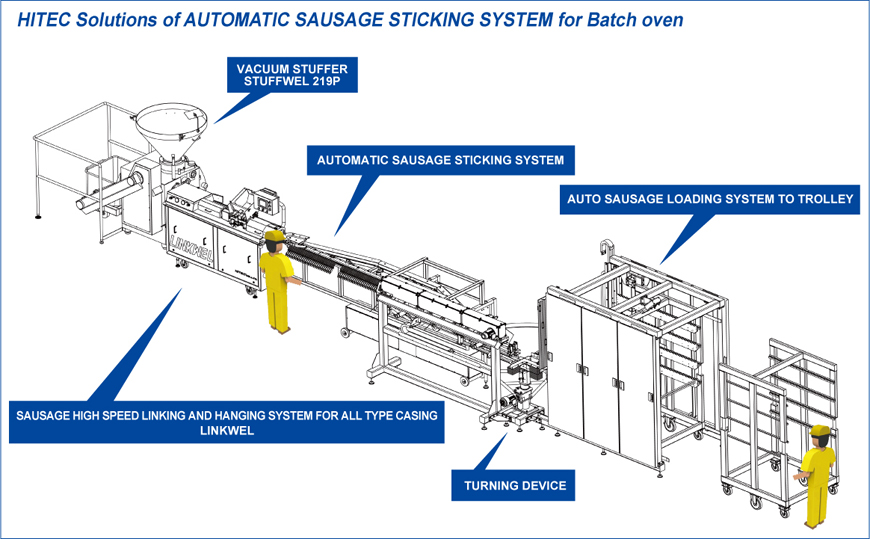

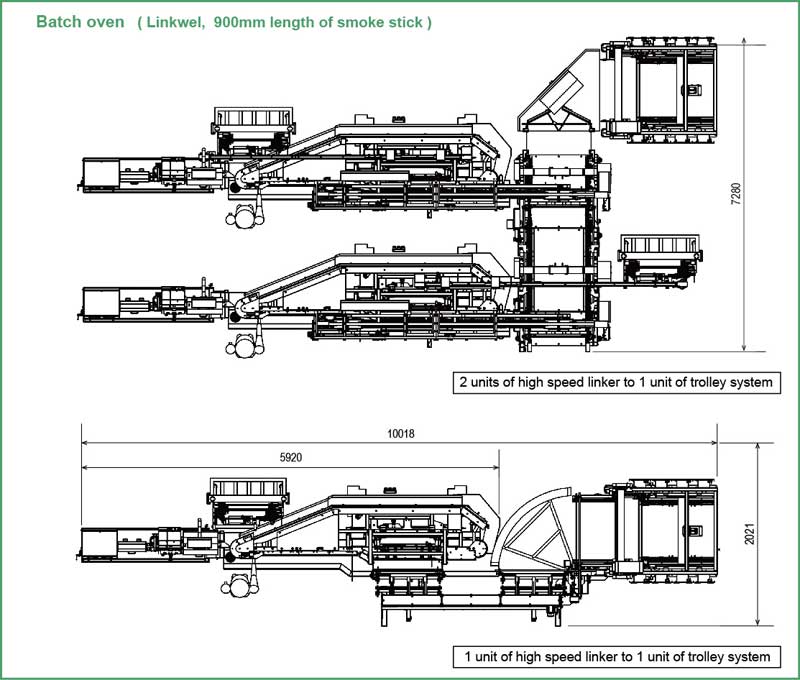

| Cycle time per stick・・・Approx. 10 sec/stick (In case 2 units of HITEC linkers set to a set of AUTOMATIC SAUSAGE STICKING SYSTEM) Casing Type・・・Natural casing, Collagen casing, Cellulose casing |

----------------Contact us!----------------

| HITEC FOOD EQUIPMENT, INC. 818 LIVELY BLVD. WOOD DALE, IL, 60191, U.S.A. TEL +1-630-521-9460 FAX +1-630-521-9466 E-MAIL information@hitec-usa.com |

CATALOG Download 【Continuous oven】 |

CATALOG Download 【Batch oven】 |

|---|

![]()

![]()